[ad_1]

In a recently published article, scientists from Carnegie Mellon University and the Argonne National Laboratory used high-speed X-ray imaging to study the keyhole effect in 3D printing based on metal powder.

A keyhole is a subcategory of void, or pore, that can sometimes be found in AM components.

Anthony Rollett, co-author of the article and professor of materials science and engineering at Carnegie Mellon University, said, "The research in this article will result in better control of the quality and better control of working with machines. "

"For additive manufacturing to really take off for the majority of companies, we need to improve the consistency of finished products. This research is a major step in this direction. "

Metal powder bed fusion

Powder bed melting (PBF) technologies use a high-power laser to melt a polymer or powder metal layer by layer until a complete 3D object is formed. PBF is one of the most used methods for 3D printing on metal. But a problem with printing on PBF metal is the formation of pores in the metal part known as "keyholes".

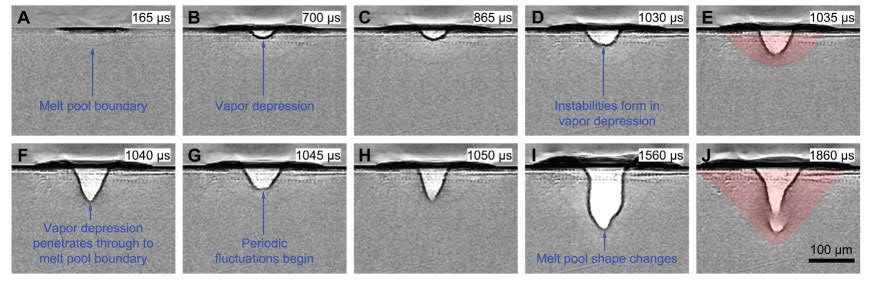

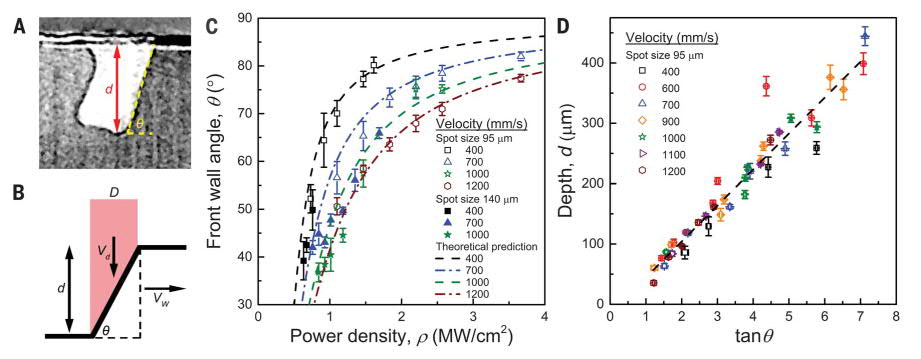

In PBF, when a laser hits the metal powder, it forms a melt. This melt expands under the effect of heat and then cools to form a solid layer. If the laser power is too high, the evaporation rate and the temperature of the melt also increase. As a result, the melt bath enters the layer forming a "keyhole" pore. The keyhole can cause cracks and general weakness of the room.

The understanding of what happens to the metal powder when it is hit by a laser is still limited. The recent paper, which used Ti-6Al-4V powder as a sample, hoped to improve our understanding of keyhole pores in 3D printing of metals.

"We are really studying a fundamental scientific problem, namely, what happens to metal when it is heated with a high-power laser," commented Cang Zhao, postdoctoral fellow at the Argonne National Laboratory. and co-author of the research.

"Thanks to our unique experimental capability, we are able to work with our collaborators on experiences that are truly valuable to manufacturers."

Synchrotron imaging

Synchrotron imaging is a non-destructive analysis used to visualize the internal structure of an object (especially microscale components such as particles).

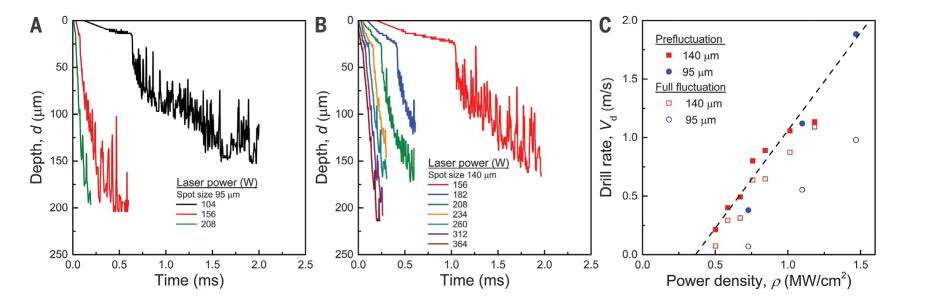

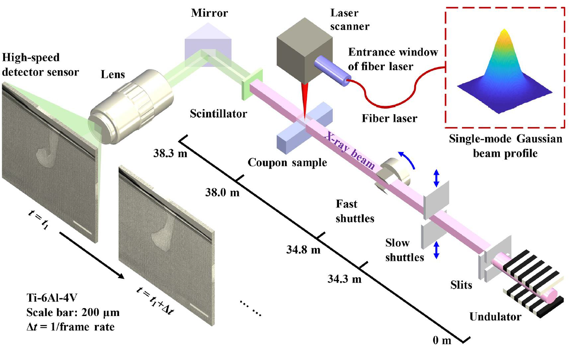

The Argonne and Carnegie study used the ultra-fast X-ray synchrotron imaging developed by the Advanced Photon Source (APS) option of the US Department of Energy (DOE) to observe the evolution of the metal during laser printing.

Tao Sun, physicist at the Argonne National Laboratory, "The keyhole phenomenon could be seen for the first time with such details because of the scale and specialized capabilities developed at Argonne"

"The intense beam of high-energy X-rays at the APS is the key to such discoveries."

Find key relationships

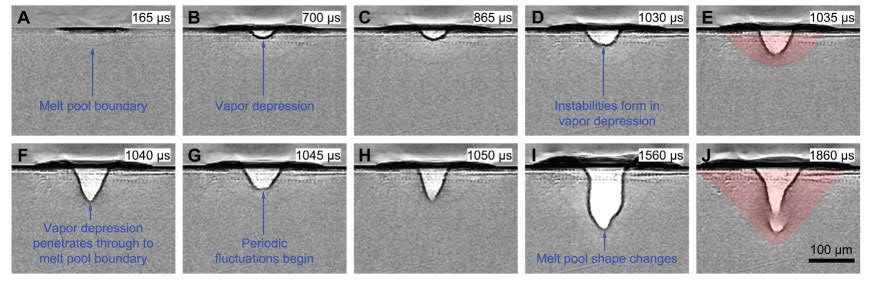

With APS technology, it is now possible to clearly observe what happens to the metal powder in contact with the laser. This allows researchers to predict certain properties of the pore, such as its depth, and to adjust the parameters of the machine.

As Ross Cunningham, co-author of the study, explains: "Based on this research, we now know that the keyhole phenomenon is more important, in many ways than the powder used in additive manufacturing »

"Our research shows that you can predict the factors that lead to a keyhole – which means you can also isolate these factors for better results."

Rollet added, "Most people think that you project a laser light on the surface of a metal powder. The light is absorbed by the material and the metal melts in a melt. In reality, you are really drilling a hole in the metal. "

"We lift the veil and reveal what is really happening."

Quality control in 3D printing

Controlling the quality of 3D printing, especially metal, is one of the most important aspects of technology, as as the number of prints needed to create a final part increases, the cost of 3D printed part also increases.

Institutes and companies have developed process control and quality assurance (QA) methods in situ. Among these are Arcam's LayerQam, photodiode-based monitoring by EOS, software and software package by Sigma Labs.

Effective quality assurance methods are essential to unlocking all the protection of 3D printing. "His [QA] important because 3D printing, in general, is rather slow […] It takes hours to print a piece a few centimeters high. It's good if you can afford to pay for the technique, but we have to do better, "says Rollett.

The research described in this article is entitled Keyhole Threshold and Morphology of Laser Fusion Revealed by Ultra-High Speed X-Ray Imaging. It was published in Science and was written jointly by Ross Cunningham, Cang Zhao, Niranjan Parab, Christopher Kantzos, Joseph Pauza, Kamel Fezzaa, Tao Sun and Anthony D. Rollett.

Appointments for 3D printing price 2019 are open. It's time to name the best academic team!

For more information on additive manufacturing research, subscribe to our 3D Printing Bulletin. You can also join us on Facebook and Twitter.

Looking for a job in the industry? Look no further than our 3D printing works board.

The presented image shows x-ray images of the vapor depression forming a keyhole pore. Image via Science

[ad_2]

Source link