[ad_1]

Unlike conventional plastics, PDK plastic monomers could be recovered and stripped of any additive compound simply by soaking the material in a highly acidic solution.

Lightweight yet robust, the plastic is excellent – until you no longer need it. Since plastics contain various additives, such as dyes, fillers or flame retardants, very few plastics can be recycled without loss of performance or aesthetics. Even the most recyclable plastic, PET or poly (ethylene terephthalate), is recycled only at a rate of 20 to 30%, the rest usually going to incinerators or landfills, where the rich material carbon decomposes in several centuries.

Now, a team of researchers at the Berkeley National Laboratory (Berkeley Lab) of the US Department of Energy (DOE) has designed a recyclable plastic that, like a Lego set, can be disassembled at the molecular level , then reassembled. a different shape, texture and color again and again without any loss of performance or quality. The new material, called poly (diketoenamine), or PDK, has been reported in the newspaper Nature Chemistry.

"Most plastics have never been designed to be recycled," said lead author Peter Christensen, a postdoctoral researcher at the Molecular Foundry of Berkeley Lab. "But we have discovered a new way to assemble plastics that takes into account recycling from a molecular point of view."

Christensen was part of a multidisciplinary team led by Brett Helms, a scientist from the Molecular Foundry of Berkeley Lab. Other co-authors are Angelique Scheuermann (from the University of Berkeley) and Kathryn Loeffler (from the University of Texas at Austin), undergraduate researchers who have been funded by the DOE's Science Undergraduate Laboratory Internship (SULI) program. The entire project was funded by the research and development program led by the Berkeley Lab Lab.

All plastics, from water bottles to auto parts, are composed of large molecules called polymers, composed of repeating units composed of shorter compounds containing carbon, called monomers.

According to the researchers, the problem with many plastics is that the added chemicals to make them useful – such as fillers that make a plastic tough or plasticizers that make a plastic flexible – are closely related to the monomers and remain in the plastic itself after he was treated in a recycling plant.

During processing in such plants, plastics of different chemical compositions (hard plastics, expandable plastics, transparent plastics, candy-colored plastics) are mixed and ground. When this amalgam of plastics cut into pieces is melted to form a new material, it is difficult to predict what properties it will inherit from the original plastics.

This inheritance of unknown and therefore unpredictable properties has prevented the plastic from becoming what many people consider the holy grail of recycling: a "circular" material whose original monomers can be recovered for reuse as long as possible, or "recycled" for recycling. to do a new one. superior product.

So, when a reusable grocery bag made of recycled plastic is worn out, it can not be recycled or even recycled to make a new product. And once the bag has reached the end of its life, it is either cremated to produce heat, electricity or fuel, or it ends up in a landfill, Helms said.

"Circular plastics and plastic recycling are big challenges," he said. "We have already seen the impact of plastic waste on our aquatic ecosystems, and this trend is likely to be exacerbated by the increasing amounts of plastics manufactured and downstream pressure on municipal recycling infrastructure."

Recycle plastic, one monomer at a time

Researchers want to divert plastics from landfills and oceans by encouraging the recovery and reuse of plastics, which could be possible with polymers formed from PDK. "With PDKs, the unchangeable bonds of conventional plastics are being replaced by reversible bonds that allow plastic to be recycled more efficiently," Helms said.

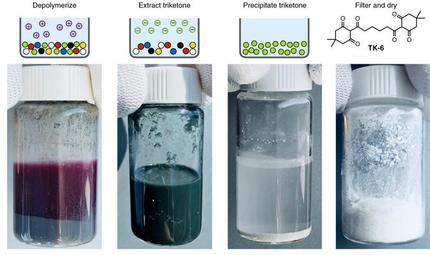

Unlike conventional plastics, PDK plastic monomers could be recovered and stripped of any additive compound simply by soaking the material in a highly acidic solution. The acid helps to break the bonds between the monomers and to separate them from the chemical additives that give the plastic its appearance and its user-friendliness.

"We are interested in chemistry that redirects plastic life cycles from linear to circular," said Helms. "We see an opportunity to make a difference because there are no recycling options." This includes adhesives, phone cases, watchbands, shoes, computer cables and hard thermosetters created by molding hot plastics.

The researchers discovered for the first time the fascinating circular property of PDK-based plastics when Christensen applied various acids to the glassware used in the manufacture of PDK adhesives, and noticed that the composition of the adhesive had exchange. Curious about how the adhesive could have been processed, Christensen analyzed the molecular structure of the sample with an NMR (Nuclear Magnetic Resonance) spectroscopy instrument. "To our surprise, they were the original monomers," said Helms.

After testing various formulations at the Molecular Foundry, they demonstrated that not only are the PDK polymers of the acid decomposed into monomers, but that the process also allows the monomers to be separated from the interleaved additives.

Then, they proved that recovered PDK monomers could be transformed into polymers and that these recycled polymers could form new plastic materials without inheriting the color or other characteristics of the original material. as a computer keyboard it is made of plastic PDK. They could also recycle plastic by adding additional features, such as flexibility.

Towards a circular plastic future

Researchers believe that their new recyclable plastic could be a good alternative to many non-recyclable plastics used today.

"We are at a critical point where we need to think about the infrastructure needed to modernize recycling facilities for future sorting and treatment of waste," Helms said. "If these facilities were designed to recycle or recycle PDK and related plastics, then we could more effectively divert plastic from landfills and oceans." This is an exciting time to start thinking about how to design materials and recycling facilities in order to circular plastics, "said Helms.

The researchers then plan to develop PDK plastics with a wide range of thermal and mechanical properties for applications as diverse as textiles, 3D printing and foams. In addition, they seek to develop formulations by incorporating herbal materials and other sustainable sources.

[ad_2]

Source link