[ad_1]

University of Maryland

Most of our construction practices are not particularly durable. The production of concrete is a major source of carbon emissions and the production of steel requires a lot of resources. Once completed, heating and cooling of buildings become a major energy sink. There are different ideas on how to deal with each of these issues, such as variations in the chemical formula of concrete or passive cooling schemes.

But now, a large team of American researchers has found a unique solution that seems to manage everything with the help of a durable material that reflects both sunlight and radiates excess heat. . The miracle material? Wood. Or a form of treated wood to eliminate one of its two main components.

With the grain

Wood is mainly composed of two polymers. One of them, cellulose, is made by binding sugars into long chains. This cellulose is mixed with a polymer called lignin, which is not really a single polymer. The precise chemical formula of its starting material can vary from one species to another and usually contains several places where chemical bonds can form, transforming the polymer into a chaotic but extremely robust mesh.

Lignin poses many problems for the production of biofuels because its variability makes it difficult to digest (cellulose, on the other hand, can be broken down into simple sugars over time). But lignin gives wood a resistance that cellulose alone would not have.

Or at least cellulose would not be in its native form in wood. The new chemical treatment essentially removes lignin from the wood. The article does not mention the precise nature of the process, suggesting that it could be complex and involve extremely toxic chemicals. However, a check of additional materials shows that the process involves emptying the wood into concentrated hydrogen peroxide and boiling it. Although I do not want to drink concentrated hydrogen peroxide while boiling, this is not a particularly difficult chemical to handle safely.

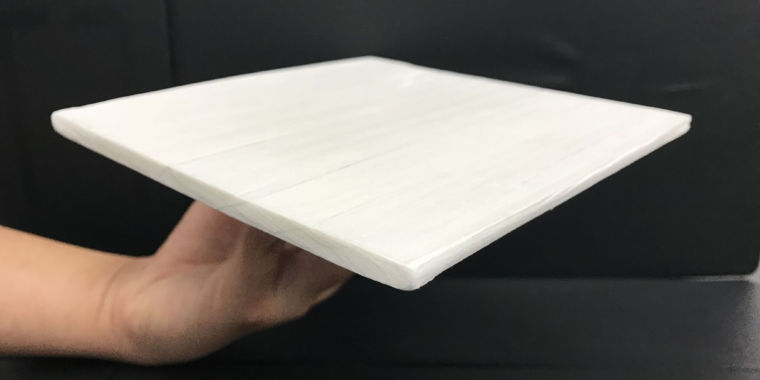

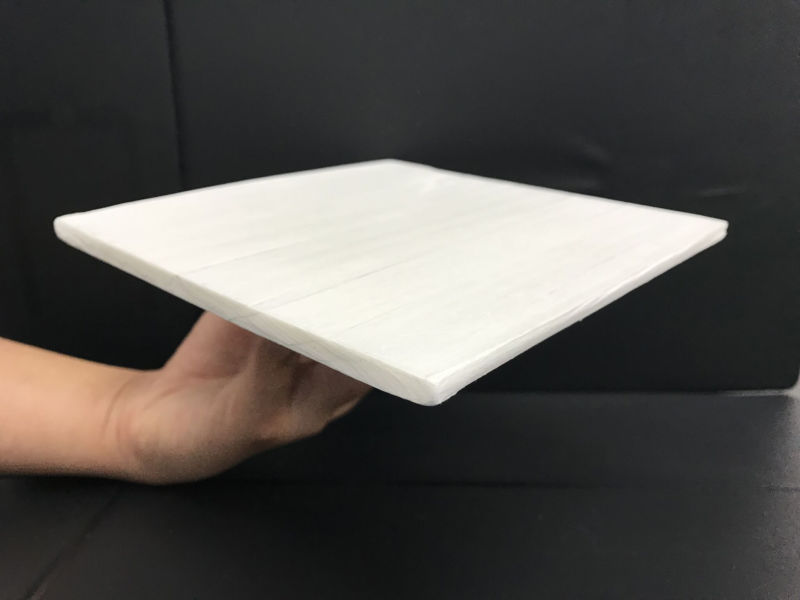

According to the description of lignin, you would expect the resulting wood to be weaker. But the chemically treated wood is then compressed. In the absence of cells or lignin to separate them, the many oxygen / hydrogen groups that depend on sugars are free to interact with one another, creating a dense hydrogen bonding mesh. This ultimately makes the material much stronger than wood (although researchers do not compare its strength to that of pressure-treated wood, which is also stronger than untreated wood).

There are a myriad of methods for measuring toughness: resistance to bending, stretching, impact, etc. The researchers measured many of these resistances. Modified wood far exceeded untreated wood by three to ten times its value. Strikingly, for at least one of these measures (tensile strength), it has slightly removed some types of steel and titanium. This means that it should be possible to use this material in places where the wood would not normally be considered.

It's cool

But rather than just being structurally useful, the wood has some properties that could make it extremely useful as a cladding covering the exterior of a building. Although most cellulose fibers are aligned along the grain of the wood, this alignment is very coarse and their orientation varies greatly. This means that the light that hits the treated wood will bounce in a dense mesh of cellulose fibers, dispersing widely during the process. The end result is a material that looks remarkably white, in the same way that a piece of sugar has a white appearance, even though every crystal of sugar that it contains is transparent.

As a result, the material absorbs poorly the sun's rays and therefore does not capture heat in the same way as ordinary wood.

But it's better. The sugars contained in cellulose are efficient emitters of infrared radiation, and they do so in two areas of the spectrum where none of our atmospheric gases can reabsorb it. The end result is that if the treated wood absorbs some of the heat of a structure, the wood can make it disappear and thus completely leave the planet. And the wood is able to do it even when it is sandblasted by direct sunlight; researchers have confirmed by placing a small heater in a treated wooden box and then exposing it to the sun in Arizona.

In the heat of the day, a square meter of wood could emit about 16W of power. At night, this figure reached 63W, for an average of 53 Watts per square meter over 24 hours. At midday, although there was no heat source in the box, its room temperature was 4 ° C lower than that of the ambient air. All this is due to the fact that the treated wood emits energy in the infrared more effectively than it absorbs in the visible wavelengths.

Around the country

What could it do for a building? To find out, researchers used a typical building model that included heat sources, such as lights and occupants, and radiation heat transfer followed by tracing. They then placed the building in 16 different US cities and tracked its energy balance over the course of a year using historical weather data. In cities in the West and South, such as Atlanta, Las Vegas and Phoenix, the materials have significantly reduced the amount of energy needed for cooling.

Researchers estimate that covering an apartment building with treated wood could save about 35% of the energy used for cooling. In a dense urban environment, this number reaches more than half. In addition, he also has the strength to manage part of the building's internal structure. And while forestry can create environmental problems, it is certainly possible to manage it sustainably.

All of this makes wood – researchers call it "cooling wood" – a very promising material. Not surprisingly, three of the team behind the new document have a patent to commercialize the technology.

Science, 2019. DOI: 10.1126 / science.aau9101 (About DOIs).

[ad_2]

Source link